AGM is a Winnipeg based glass manufacturer that supplies the residential and commercial industry with all their glass needs. With growth and an expanding product lineup being able to safely lift, process, and manufacture their products is paramount to their production and manufacturing plans.

AGM Glass Case Study – a clear example of safe lifting

The CHALLENGE

Over the years AGM has grown and so too has their product offering. Now serving both the home and commercial markets for glass the size of the products have become larger and larger. With more demand and larger glass offerings, the need for robust and versatile lifting equipment throughout their facility that could also handle tomorrow’s needs became an important central decision for operations. As well, safety concerns are always at the forefront when handling their product, providing safe conditions for employees, confidence in the equipment, and to increase the speed of operations.

We want to make sure our people are safe and healthy, and come to work every day.

Marty Kania, General Manager

The SOLUTIONS

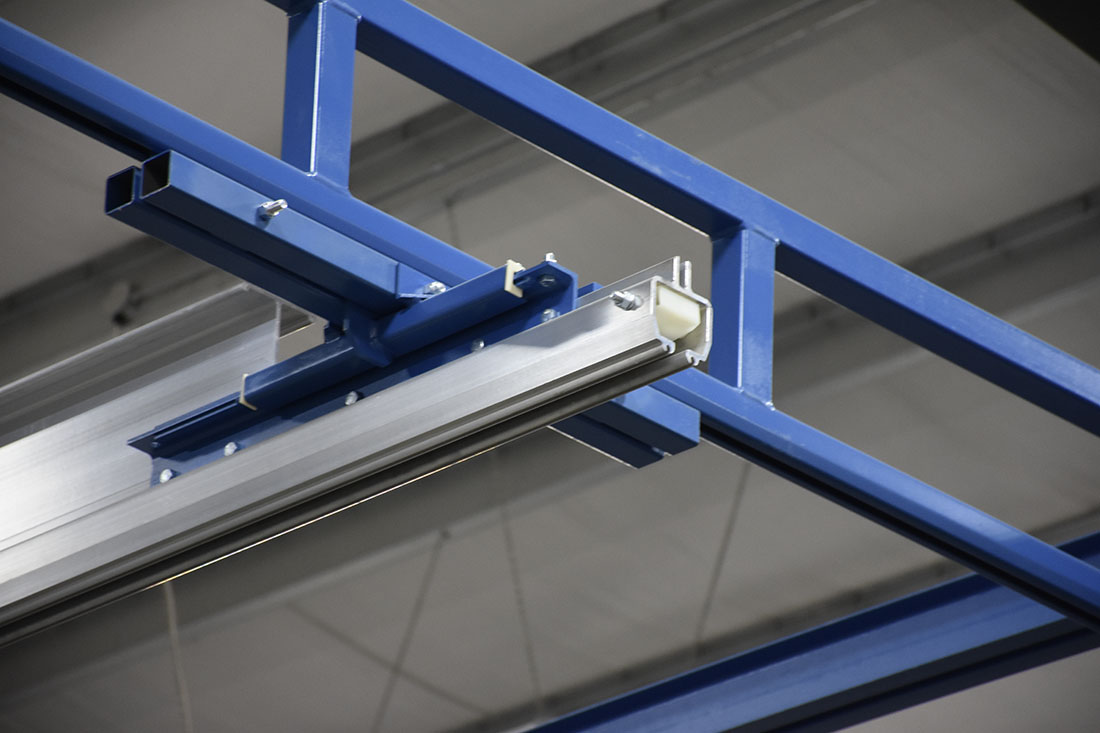

Partnering with Acculift over the years, AGM has grown its operations and glass handling capabilities. Expanding product lines, increased capacity, and additional production space have all necessitated solutions that can grow and change with AGM. Working closely with their operations manager, Acculift has provided custom solutions that are modular in nature and can be altered or relocated to match shifting production requirements. From higher hook heights to cantilevered headers, to a ceiling mount lift system, to individual tool solution cranes, Acculift has been able to provide the equipment and ideas AGM requires to expand it’s operations safely and efficiently.

Calculate the ROI on an upgraded crane system for your business using this quick online form.