A Workplace that can Move is a Workplace that can Grow.

Our extensive experience and strong reputation has been earned over 30 years and allows us to equip your facility with the best-in-class lifting solutions. From the bridge to the hook, and everywhere in-between, we understand what it takes to move your goods. Acculift is the preferred lifting solution in Manitoba and Saskatchewan for workstation bridge cranes for manufacturers.

What types of Building Cranes are there?

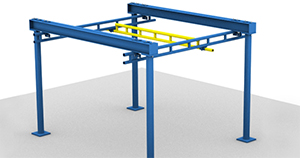

Bridge workstation cranes are most commonly seen in manufacturing and industrial workstations (or work cells). Bridge cranes provide unrivalled reach and movement of your load. They are typically used in individual task workstations but can be extended to fill the entire facility. With modular designs, multiple hoist capabilities, and bolted floor columns, bridge cranes are extremely versatile and can be custom designed to suit almost any space and need. Overhead cranes are typically for heavier loads and use the buildings structural components as part of the crane system.

Call us for overhead crane quotes and estimates or crane part quotes.

Monorails

Monorails