19 Jul The Parts of a Crane

All you Need to Know

To increase your understanding of workstation and overhead crane components here is a list and explanation of the most common parts of any lifting system. Depending on the type of crane (workstation vs. jib crane for example) not all components may be in all cranes or may be different than shown here. Each lift is unique. As always, contact your Acculift representative for additional details.

Hook

The load is supported using a hook which connects to the hoist and to the end effector. From our experience in inspections the latch kit is the part that most often will need replacing.

Hoist

The hoist is what creates the lift in lifting systems by holding, raising, or lowering, the load using wire rope or chains. Hoists can be hand powered, electrical powered, or with compressed air (pnuematic). Choosing the right hoist for your lifting is crucial to having a system that will meet your lifting needs (like the new SEQ from Kito, now available in Canada).

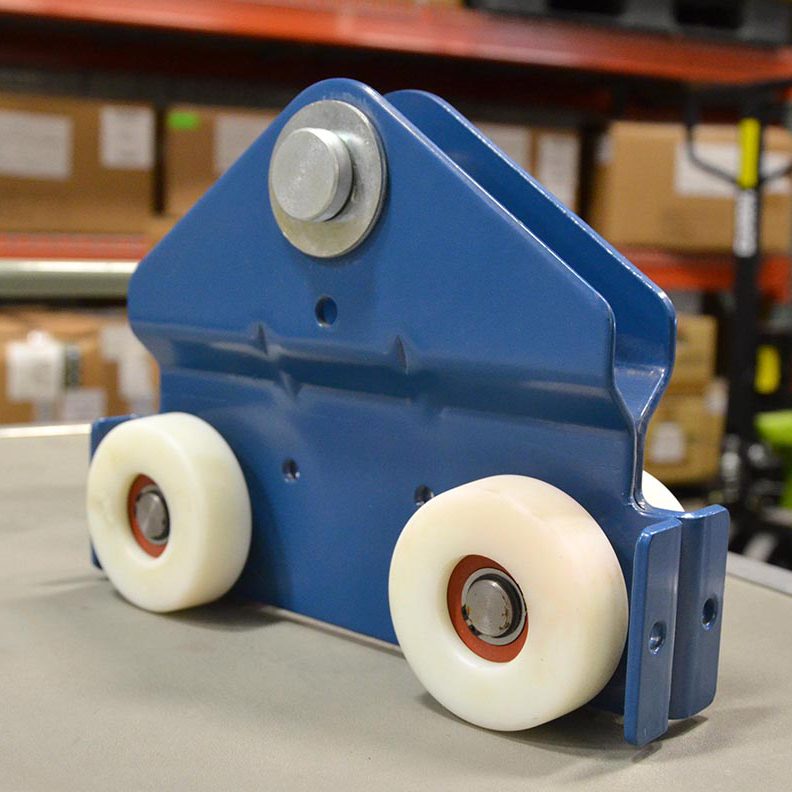

Trolley

Trolley’s support the hoist and moves along the crane’s bridge. Trolley’s can be configured to be top-running or bottom-running, and can be within a track system or run on a beam.

Bridge

Bridges are the load-bearing component that runs the width of the crane system. This is the primary structural component of a lift that connects the runways and holds the hoists and trolleys. Bridge’s can be single or double beam. They can be of an enclosed box style or beam/girder fabrication, dependent on your needs and the load classifications of the work performed.

Columns

If the crane support system isn’t part of building it will need columns to support it. How high your columns are will determine your head room and how high your lift can go. Jib cranes are one-column supported while overhead cranes will have as many columns as needed to safely support the lifting system. Columns are all built to the size needed by your environment to maximize the lifting hidght.

Controls

Controls can be mounted, battery powered remotes, or a hanging pendant variety. The controls operate the drive and hoist motors to control the hoist and the speed for precise load positioning. Most crane systems can be retrofitted with remote pendants (remote operation is a safer alternative in many situations).

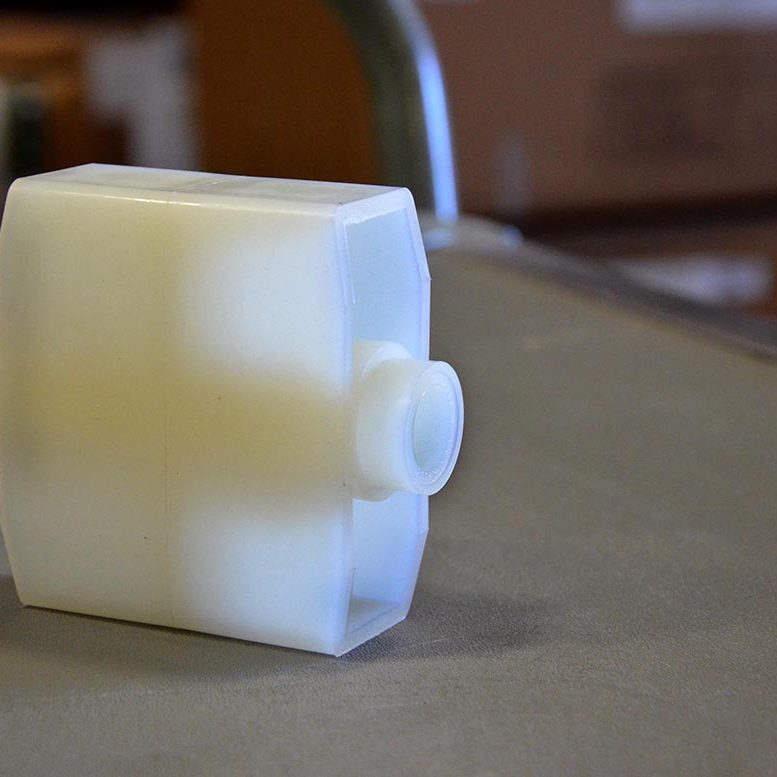

Bumpers

Designed to reduce crane impact and energy bumpers bring the crane to a controlled rest and stop by minimizing the force at which the crane reaches the end of travel. Bumpers can be attached to several components of a crane. Bumpers are also called crane stops. Replacing worn bumpers can extend the life of your crane.

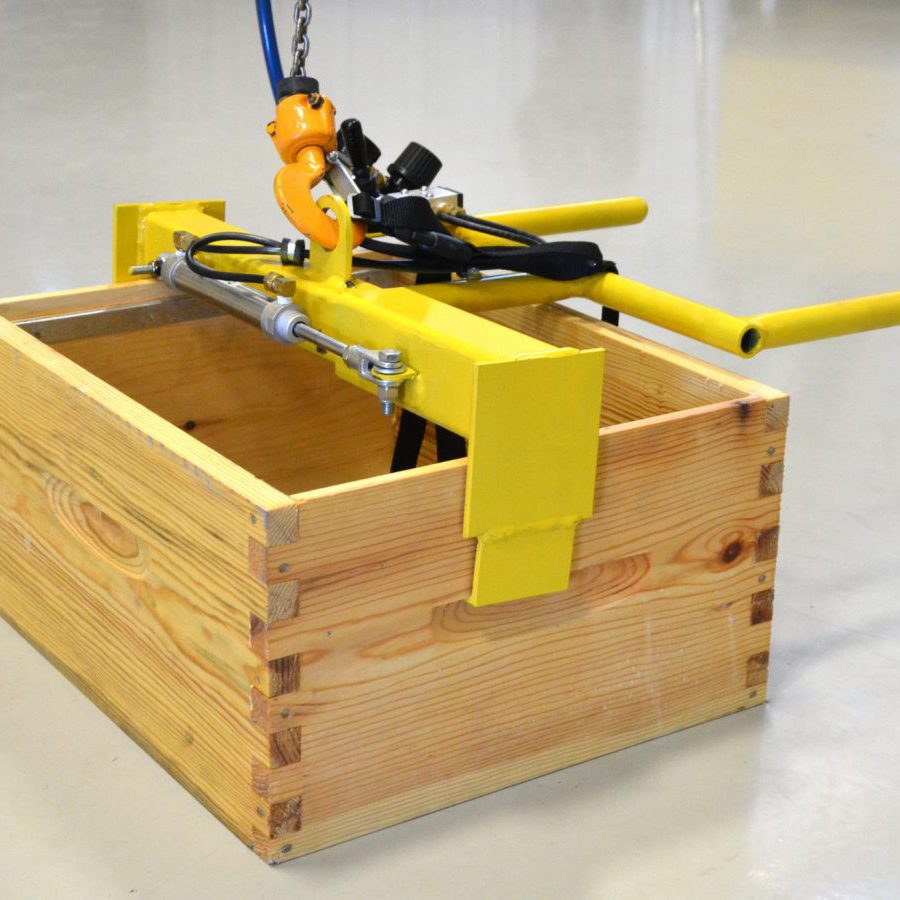

End Effectors

End effectors are the “grab” part of the crane system. They can be as simple as cabling or strapping, and there are many stock solutions for loads, but end effectors are most effective when designed to lift YOUR specific load. A custom end effector for your load lifting is safer, faster, and more precise. Your Acculift representative can show you what custom below-the-hook options are suitable and you can see some of the many options available for end effectors right here.

Use our vast product knowledge to your benefit

and let us help you select the right system for your job.

We are Canada’s leading supplier of high-performance lifting solutions, offering quick delivery and installation times backed by the industry’s best warranty. Contact us today to arrange a consultation, (204) 837 8367 or Toll Free at 1 888 317 8880. We have offices in Winnipeg, MB, Regina, SK, and Surrey, BC (serving all of the Greater Vancouver region and BC).