Superior Ease of Movement of Sheet Steel

A Success Story of a Jib Crane with Vacuum Lifter

A manufacturer of air distribution products had purchased a new CNC laser. They required a means of transporting single sheets of steel from palletized stacks onto the laser table.

The CHALLENGE

The steel sheets measured up to 5’ x 10’ and ranged from 0.020” to 0.5” thick. The thicker sheets would be far too heavy to manhandle and the thin sheets would be too awkward for even two operators to lift because of their flexibility. Loading the sheets with a forklift can cause damage to the material and the laser table, and is also very inefficient. This method requires a readily available forklift and a qualified operator, and loading on and off the forks is time-consuming and unsafe.

Our APPROACH

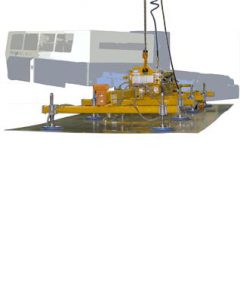

Acculift designed a lift system that coupled a free-standing jib crane with an electric-powered hoist and vacuum lifter. The jib crane features a lightweight enclosed track boom to provide superior ease of movement and precise load positioning. Because of the relatively small area to be covered, a jib crane was the perfect fit and an economical solution. The two-speed electric hoist provides smooth and reliable lifting control. Because of the range of sheet thickness, an eight-pad vacuum lifter was selected to provide the capacity for the larger sheets as well as added stability for the flexible, thin sheets.

The RESULTS

One operator is able to lift, transport and load the sheets from the stacks to the laser table. The operation runs smoothly and efficiently, with minimal manpower. Accidents and injuries in this area are now non-existent. The system took less than a year to pay for itself and has provided a safe, productive work cell.

I wouldn’t be on this job if I had to lift them by hand. Using a forklift is dangerous and you can get damage [to the product] – but this handling solution puts the sheets down gently.