16 Feb Vacuum Lifters Versatility in Manufacturing Facilities

Move More with a Vacuum lifter.

Many manufacturing and distribution centers don’t consider vacuum lifters as a viable solution to repetitive moving in their facilities. For Acculift, this is a problem we hope to address, as vacuum lifters are incredibly versatile end effectors (sometimes called the “below the hook” device) that can move a variety of materials of considerable weight. Combined with a G-Force and rotate-tilt mechanisms they can provide accurate and very precise handling abilities – perfect for getting that glass or sheet metal EXACTLY where it is needed.

Myth #1: “They only work on flat surfaces.”

Yes, there are vacuum lifters specifically built for flat surfaces such as sheet metal and glass, and that is what most people traditionally think of when they hear the term “vacuum lifter”, but in fact, there are end effectors built specifically for handling non-flat loads. With a foam end effector, you can move luggage, dog food bags, feed bags, cartons, cardboard boxes, corrugated steel and more.

Lifting bags is a basic part of many agricultural production processes and vacuum technology is the way to do it safely.

Vacuum bag lifters are used to lift and place bags onto pallets or bins (many food manufacturers split and empty the bags into the processing containers this way). Manual lifting of bags is often a hazard due to the awkward grip or height of the lift required and through the sheer repetition of movement of the bag handlers. Most bag materials are airtight so that standard suction feet can be used to lift and move the bags. With porous materials, such as feed bags, a rubber skirt is attached to the suction foot to compensate for the air leakage.

Myth #2: “Vacuum lifts only work on lighter loads.”

That all depends on what you consider “light”. Is 300 lbs light? 600lbs? 3000lbs? Vacuum lifters can be designed for any load and can securely lift full sheets of metal, large heavy glass windows, loose bags of seeds, heavy luggage, and lots more. The suction volume of the lifter dictates the weight it can grab, which can be substantial, but it is the crane and hoist system that ultimately dictate maximum loads.

Myth #3: “The load is awkward to position with vacuum lifters.”

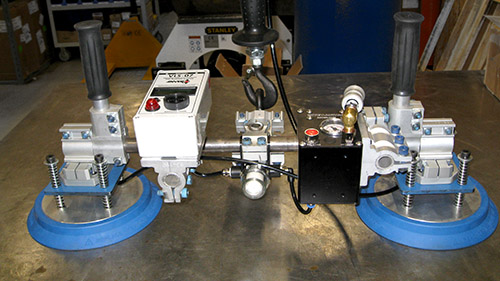

The vacuum lifter is only part of the lifting solution – the part that “grabs” the load. The operator positions it where it needs to go and in this aspect, you have a lot of choices with the swivel points of your lifter dictating maneuverability. With many swivel points built into the lifting mechanism, the load can be placed exactly where you need it to be and with complete control the whole time. Lifting mechanisms can tilt and rotate the load and with the multi-speed control you can handle heavy, delicate objects, precisely.

In this video, we demonstrate a vacuum lifter with tilt and rotate capabilities. This system also has variable speed control, and when combined with the Gorbel G-Force intelligent lifting system, you will see how truly versatile vacuum lifters can be and how they can fit into your production line at your organization. Contact us for a demo.

Types of Vacuum Lifters

There are two types of vacuum lifters, continuous lift, and vacuum lifters. The continuous lift provides constant vacuum pressure for material handling where the load and vacuum may lose suction – such as canvas bags or objects that warp when lifted. A constant vacuum pressure system ensures that the load is lifted, and maintained in the lift, safely. Specific vacuum pads are required for this type of lift that have a larger lip that maintains suction. Most lifts; however, will use standard vacuum lifting mechanisms that “lock on” to the load and don’t require constant vacuum pressure. These systems have gauges and alerts to maintain the vacuum pressure for safe lifts.

Types of Pads

What you are lifting and moving will dictate the type of pad (end effector) you will have installed and will dictate the type of lifter you will use. Here are some of the types of pads available and their applications with many more varieties for even more varied load control.

| Pad Attachment Type | Max. Load Capacity | Applications | Key Features |

Single Pad Attachments | 150 to 2300 lbs. Single Pad Attachments | For heavy sheet and plate loads found in the primary metals industry and service centers. Rugged design for heavy production use. | Deep profile sealing edges for heavy capacity and wavy plate. Tough Sealing rings bolt on between two metal plates. Rugged welded construction of pads for long term durability. Top metal ring protects seals. |

Inline Multiple Round Pad Attachments | 200 to 1100 lbs. Two, Three, Four and Five Cup Attachments Beams Lengths of 24″, 36″ and 48″ | Small loads Multiple items Long narrow loads which are 7.13″ (181 mm) or wider | Slip on or Snap Round Seals that are Hand Replaceable for fast replacement with no tools. Pads are Fully Adjustable Ability to Shut-off outside cups on three and four pad attachments |

Pad Attachments with Rectangular Seals | 750 to 2200 lbs. One and Two Pad Attachments | They are excellent for metal, glass, wood, composites, curved panels, stone and other materials. They feature a good versatile design for most smooth applications. | Rectangular vacuum cups designed. for handling flat, rigid materials. Dual Pad Attachment offers multi-configuration suspension, easily changes pattern by means of a clevis pin into one or multiple two pad configurations. |

Rectangular Pad Attachments for Heavy Loads | 3000 to 6400 lbs. One and Two Pad Attachments An economical alternative to multiple pad vacuum lifters. | Heavy Duty Bolt-On rectangular pad attachments. For heavy sheet and plate loads found in the primary metals industry and service centers. Rugged design and large capacity for mill duty use. | Long big sealing edges for heavy capacity and wavy plate. Tough Sealing rings bolt on between two metal plates. Rugged welded construction of pads for long term durability. Top metal ring protects seals. Compact and extra tough. |

Standard Round Foam Pad Attachments | 500 to 2000 lbs. | Foam seals for rough surfaced porous and semi-porous loads. Stone with a saw cut or blasted or flamed surface, concrete and rough wood. | Machined lip to insure the seal stays in position. Long lasting foam seals handle both smooth and rough stone. Replacing worn seals can be done in under a minute by hand without tools. |

Standard Rectangular Foam Pad Attachments | 500 to 2000 lbs. | Foam seals for rough surfaced porous and semi-porous loads. Stone with a saw cut or blasted or flamed surface, concrete and rough wood. | Machined lip to insure the seal stays in position. Long lasting foam seals handle both smooth and rough stone. Replacing worn seals can be done in under a minute by hand without tools. |