27 Feb Top Running and Under-hung bridge crane configurations explained

Years of experience enable us to best help you select the overhead bridge crane that will suit your needs. There are many considerations we take into account in our analysis of your site and needs. Below are the most important ones in choosing a top running or under-hung bridge crane.

Overhead bridge cranes can have many different configurations and the primary options to consider are one or two beams (more often referred to as a single girder or double girder design), freestanding or building supported, and finally, top running vs. under-hung. Whether the bridge is top-running or under-hung is dependent on the design of the building structure and the space requirements needed for lift operations. You’ll want to give careful consideration to make sure that you understand the requirements of the lifting task and the environment where the crane will be operating to make the right decision of top running or under-hung system. Here are some of the questions that help us determine the best suit for your needs:

- Can the existing support structure be utilized or will a freestanding support structure need to be built?

- Are there existing runways in the facility that the crane can be installed on?

- What is the max load weight you’ll be lifting?

- What type of overhead room is available?

- How high will your lifts need to be for the work you are performing?

- Hook approach – how much of the crane’s bridge will the hoist trolley need to utilize?

- How important is free and clear floor space?

Top running double bridge crane.

Top running bridge cranes

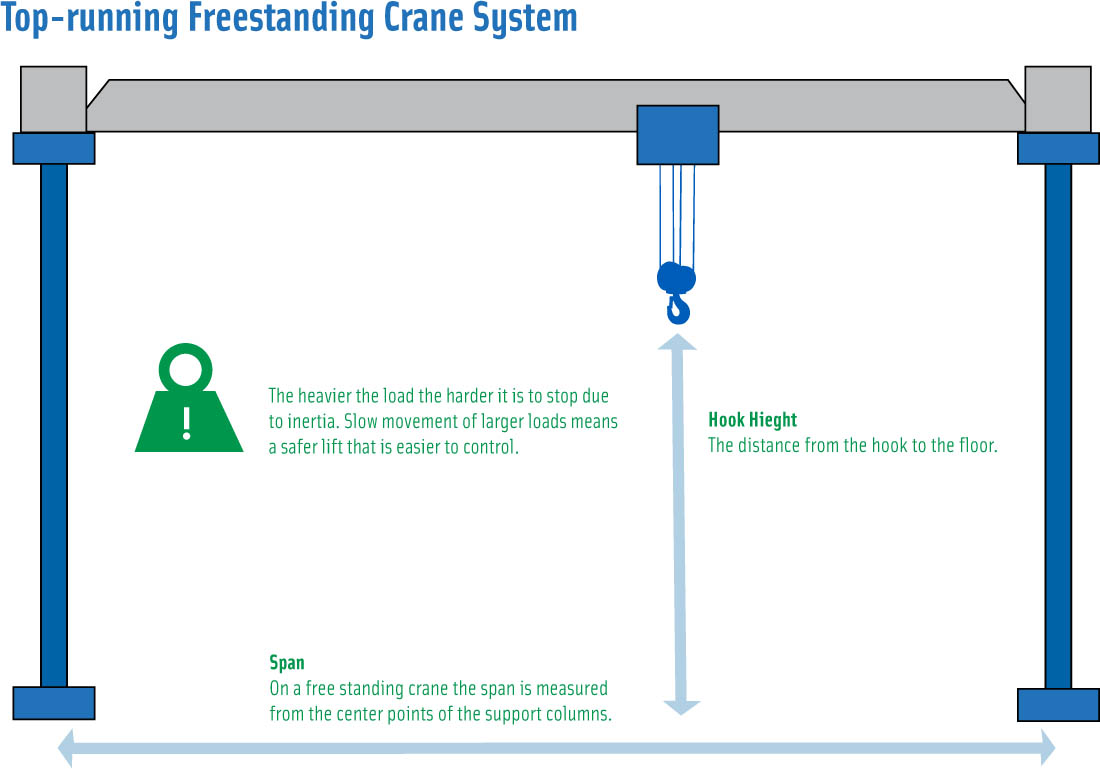

Long bridge spans are more easily achieved with a top-running crane configuration, and in addition, the hook height (the distance from the floor to the hook) is greater giving the user much more headroom for lifts. As extra supporting structures are used, this configuration is suited to a much higher capacity for large lifts.

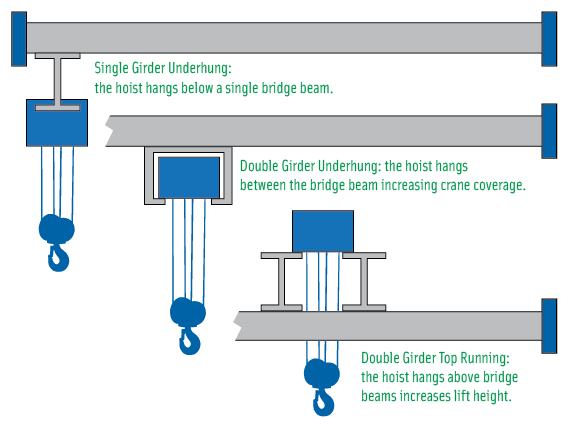

A top running overhead crane has a fixed rail or track system installed on the top of each runway beam allowing the end trucks to carry the bridge and hoist along the top of the runway system. Top running cranes can be configured in a single girder or double girder bridge design. A single girder bridge utilizes an under-hung trolley and hoist, while a double girder design most often utilizes a top running trolley and hoist.

Top running overhead cranes have no limiting capacity meaning that they can be built to handle small capacity loads or large capacity loads. Top running cranes can be built to capacities of anywhere from 1/4-ton to excesses of 100-tons. These types of overhead cranes are supported by the building structure or runway support columns and are ideal for moving extremely heavy loads.

Top running cranes provide added lift height for buildings with limited headroom because they ride on rails on top of the runway beam. A top running double girder bridge design allows the greatest lifting height because the hoist and trolley run on top of the two bridges or girders adding anywhere from an extra 3 to 6 feet of hook height.

Top running overhead cranes are typically larger than under running cranes, as they can be built to higher capacities and can accommodate wider spans. Because the crane is supported on rails on top of the runway beams there is no suspended load factor, so installation and future maintenance is easier and less time-consuming than an under-hung crane.

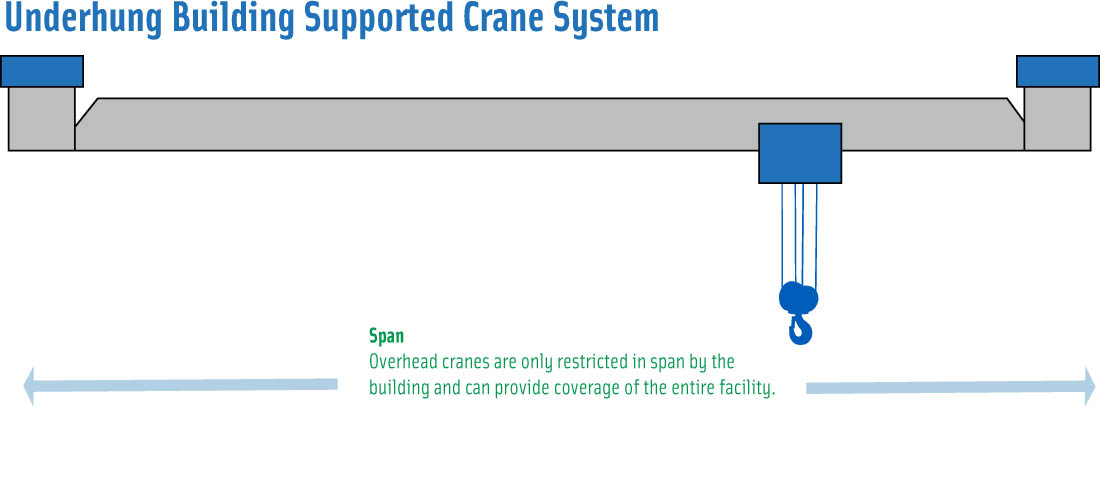

Under-hung crane configurations

Typically tied into the building structure itself, under-hung bridge cranes don’t require column support structures IF the building structure can support the crane. Without the need for support columns, this type of configuration allows for more crane service area coverage. The work area below the crane is completely unobstructed by columns which is advantageous in facilities with limited floor space or complex processes. This comes at the cost of hook height. Under-hung crane configurations typically have a reduction in the distance of the hook to the floor. Overall, your priorities in crane configuration are determined by your lifting needs and the building itself.

An under-running crane, or commonly referred to as an “under-hung” crane uses wheels that are supported by the bottom flange of the runway beam to move the bridge up and down the runway. Under-hung cranes are most commonly configured in a single girder design for lighter service and lower-capacity applications. They can also be built in a double girder design for higher capacities or more hook height where needed.

An under running single girder crane will utilize an under running hoist and trolley which moves across the bottom flange of the bridge beam. A double girder under running crane can run its hoist and trolley along the top or the bottom of the bridge beams.

Under-hung cranes also offer excellent side approach and maximize utilization of the building’s width and height when supported by roof or ceiling structures. They’re ideal for facilities that lack vertical clearance to install a top-running overhead crane system.

Also, there are options for single or double beams for both top-running and under-hung cranes. Double beams are used in higher capacity cranes without having to go to a substantially larger single beam for the same weight in the lift.

Hopefully, this gives you a better sense of whether a top running crane or an under-hung crane will be the most beneficial for your lifting needs. To sum up, under-hung cranes offer flexibility, functionality, and ergonomic solutions, while top running crane systems offer the advantage of higher capacity lifts and allow for higher lift heights and more overhead room.

Use our vast product knowledge to your benefit

and let us help you select the right system for your job.

We are Canada’s leading supplier of high-performance lifting solutions, offering quick delivery and installation times backed by the industry’s best warranty. Contact us today to arrange a consultation, (204) 837 8367 or Toll Free at 1 888 317 8880.