Application

Jib cranes lift and transport materials in semi or full circles (360 degrees) around their support structure. They can also move materials to adjacent workstations, as in assembly line environments. Hoists, manipulators, balancers, or other workstation tools (i.e., welding wire feeders) can be installed on the jib cranes’ booms dependent on the need of the operation. Tool solution jib cranes are a light-weight, small footprint, crane that are designed to be a durable, lightweight option for applications with suspended tooling, tools, or light duty lifting (vacuum lifters are also an option on jib cranes). Many tools are cumbersome to operate all day so tool solution jib cranes take the lifting out of the work, enabling operators to avoid repetitive stress lifting issues. The small footprint of these cranes makes installation possible in small areas, such as between machines enabling safer long-term use of heavy tools by operators.

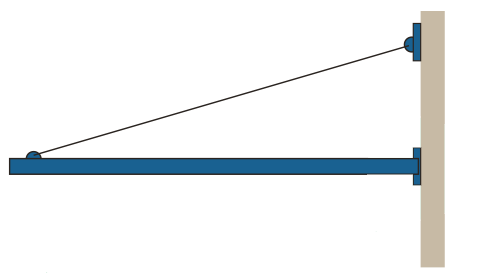

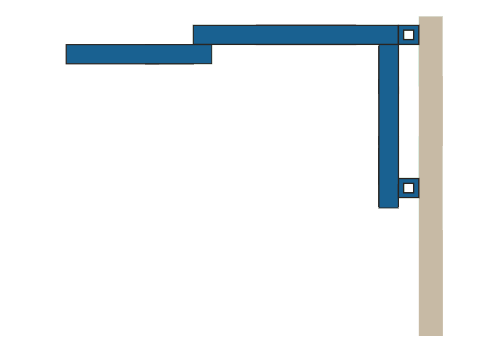

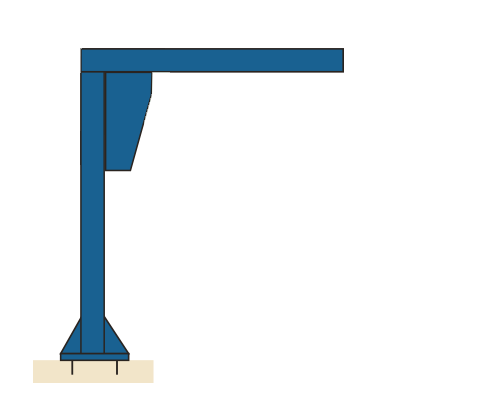

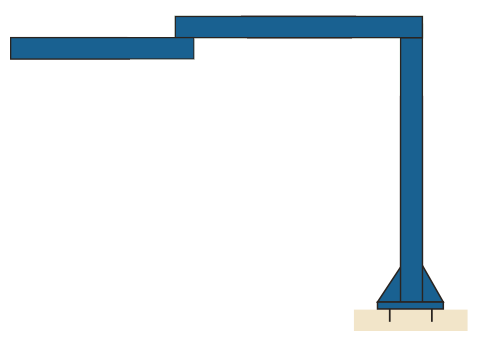

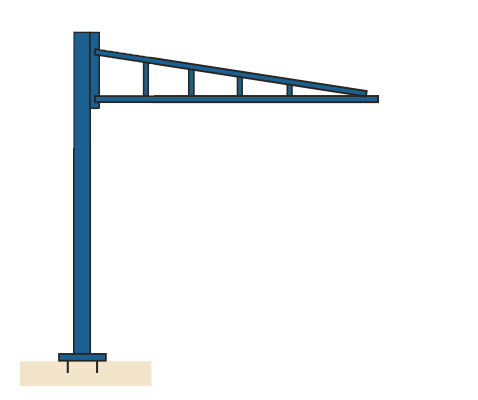

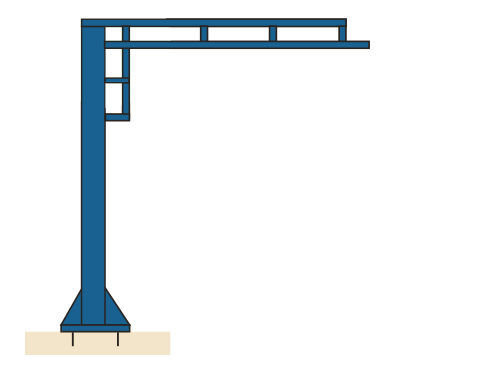

Jib cranes have many options, either be free standing or wall mounted, enclosed track or I-Beam, depending on the priority of needs. Free-standing jib cranes offer a full 360 degrees of load movement and can support heavier loads whereas wall mounted jib cranes require no floor space and can fold out of the way but offer less range of movement. Enclosed track jib cranes offer smooth and easy movements of the load while I-Beam jib cranes have a much higher capacity. And the location of the crane also plays a huge factor in the type of crane you would select for that workstation. There is a jib crane configuration that will suit your needs perfectly.

We compare different advantages of jib cranes and overhead workstation cranes in this infographic.