29 Jun Lift Tables and Scissor Lifts – the small but mighty workstation lift

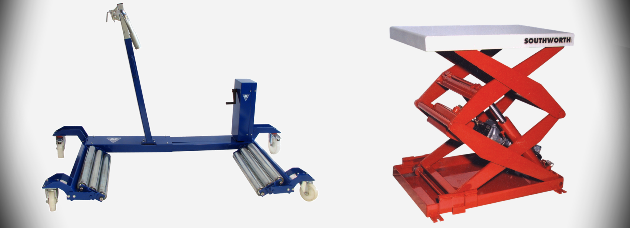

A powered lift table is a device that employs a scissors mechanisms to raise or lower goods.

Typically, lift tables are used to raise large, heavy loads but only for relatively small distances. Common applications include pallet handling, vehicle loading and work positioning. Lift tables are a recommended way to help reduce incidents of repetitive stress disorders by correctly re-positioning work at a suitable height for operators. By their nature lift tables lend themselves to being easily adapted to a specific use and user.

Many people confuse lift tables with scissor lifts and while the lifting concept is the same (scissor extension) there are two fundamental differences. The first is that lift tables are primarily used to move the product, positioning a load exactly where you require it, or to work on it without strain on yourself. Scissor lifts move you to where the work needs to be done. Which leads to the other difference, lift tables have a smaller range of movement than a full scissor lift, lifting tables are about control, not height.

Many people confuse lift tables with scissor lifts and while the lifting concept is the same (scissor extension) there are two fundamental differences. The first is that lift tables are primarily used to move the product, positioning a load exactly where you require it, or to work on it without strain on yourself. Scissor lifts move you to where the work needs to be done. Which leads to the other difference, lift tables have a smaller range of movement than a full scissor lift, lifting tables are about control, not height.

And don’t discount the lifting capacity of a lift table. You can order a lift table to suit your specific weight requirements. Some heavy duty lift tables can lift 25,000 lbs! Since lift tables don’t move products very far (relatively speaking of course) they can move very heavy loads. But when sourcing a lift table, look for one that has 20% more capacity than you currently anticipate moving. This will give you enough flexibility in the future for a wider range of use in case your needs or product change.

Examples of Lift Tables in Use

There are literally hundreds of uses for lift tables in manufacturing, warehousing and distribution facilities. And in every case the addition of a powered lift makes the job faster, safer, and easier. Some typical applications include: machine feeding, product assembly, inspection quality control repair, feeding and offloading conveyors, repair tables, or perhaps being the bridge between different levels. A typical us we’ve seen is motorcycle repair shops using lifting tables to enable their technicians to work at a standing level on the engines of the bikes.

Lifting tables can tilt heavy articles safely. That’s the key benefit of a task specific lifting table, the operator isn’t under strain or stress to manipulate the load and the load is controlled at all times during the tilting maneuver.

Industries that commonly use lift tables include woodworking, upholstered furniture manufacturing, metalworking, paper, printing and publishing, warehousing and distribution, heavy machinery and transportation. Even dog groomers use lift tables! For our purposes, here are some of the more common uses for lift tables in manufacturing:

Industries that commonly use lift tables include woodworking, upholstered furniture manufacturing, metalworking, paper, printing and publishing, warehousing and distribution, heavy machinery and transportation. Even dog groomers use lift tables! For our purposes, here are some of the more common uses for lift tables in manufacturing:

Container Lifting

Accessing parts in containers is one of the most significant productivity thieves in any manufacturing or assembly operation. Getting at parts in the bottom of containers is difficult and requires workers to bend and lift to get them out. There are lifting tables designed for wire containers bringing the parts closer to where the worker needs them.

Pallet Manipulation

More goods are shipped on pallets than any other packing mechanism. Speciality pallet lifting tables can manipulate pallet loads and can help you break a pallet down, rotate the load, or bring it to the level you need to work off of the pallet. The speeds up the process considerably and increases productivity of the employee.

Task Specific Lifting Tables

What prompts many customers to look into lifting tables is a specific need or product that needs manipulation. And so there are lift tables for all measure of products, from gun safes to cage containers, at all different load lift sizes.

Gun storage lifting table is an interesting application as a pallet jack is used in conjunction with the lifting mechanism for this heavy load handling. Gun storage safes can be as large as 3’wide x 5’ high x 2’ deep and weigh up to a ton. Sold at the retail level stores require a way to safely position the safe on the owners vehicles as loading the larger models into an SUV, van or a pick-up truck is an extremely difficult and dangerous task. Often several employees are required to lift, tilt and push them onto or into a vehicle. Using manual hand controls on the gun safe lifting table, an operator can position the gun safe from a vertical position to a horizontal position when loading it into a pickup or into a vehicle or trailer.

Each lifting table is as unique as the organization it goes into. Contact ACCULIFT today, let’s talk about your needs, schedule a demo, and get you lifting right.