15 Feb Collectors – Components of an Overhead Lift

Collectors on an overhead crane system are contacting devices for collecting current from the runway or bridge conductors.

Collectors play an important role in providing electricity to the hoist and other components of the crane. As the crane is in motion over long distances a fixed wiring system is not feasible. Collectors move with the bridge of a crane and provide electricity at all times to the systems.

Mainline collectors are mounted on the bridges to transmit current from the runway bars further into the system, and trolley collectors are mounted on the trolleys to transmit current from the bridge conductors.

Overhead view of runways on a crane. Note the three orange for power and 1 green for ground.

Running the length of the crane, runway bars conduct electricity down the length of the crane and pass electricity to the mainline collectors. Made from steel and copper, these bars have a plastic protective guide around them (the bright distinctive orange for power and green for ground), to keep dust/grime off so they don’t short out. At one end, the runway bars are connected to the electrical panel which provides power for the entire crane.

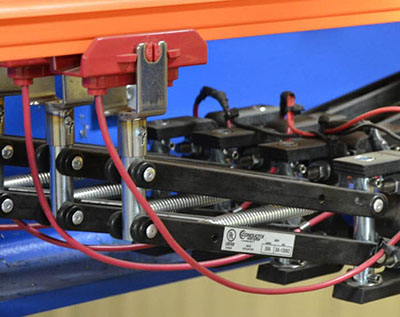

As even the smallest delay in transmitting electrical current could shut down the system, collectors typically have a dual system (two points of contact) to ensure a constant flow. On either side of the collector, springs keep the points of the collector in contact with the bridge conductors as the crane bridge moves. Typical of longer systems, there will be joints which can disrupt the flow of electricity as the collector moves across them. By having two points of constant contact, electrical disruptions to the system are prevented.