Acculift – Dedicated to Elevating Your Business

Our Promise

Acculift has been providing dependable service to the manufacturing industry since 1985. With our expertise in ergonomic lifting systems and overhead cranes, Acculift is dedicated to the results our clients are striving to achieve. Our team takes the time to understand your unique needs and challenges in order to develop a comprehensive solution that will help create a safe and productive workplace. We hold ourselves accountable and are there for our customers from initial project planning through to installation and after-sales support.

Our solutions are proven to reduce workplace injuries,

increase productivity, and grow your business.

Acculift has grown from a small team distributing industrial tools to the industrious company we are today – yet our values remain the same. We pride ourselves on being a dedicated team that takes what we do and your successes, personally. And to us, that’s what really matters. Our team is comprised of industry experts, dedicated service personnel, and an installation crew that is second to none in Canada. From our office staff to our installers, Acculift is focused on the benefits and value we bring to our clients.

Complete End to End Solutions

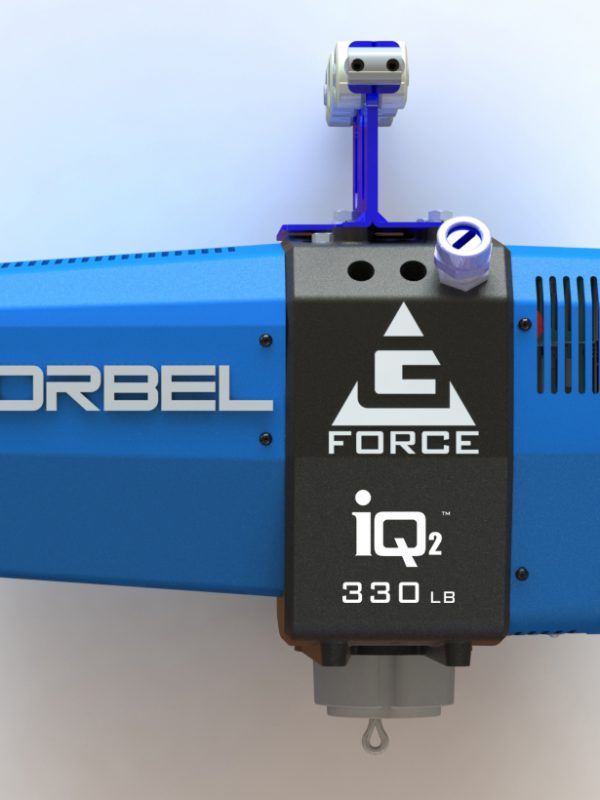

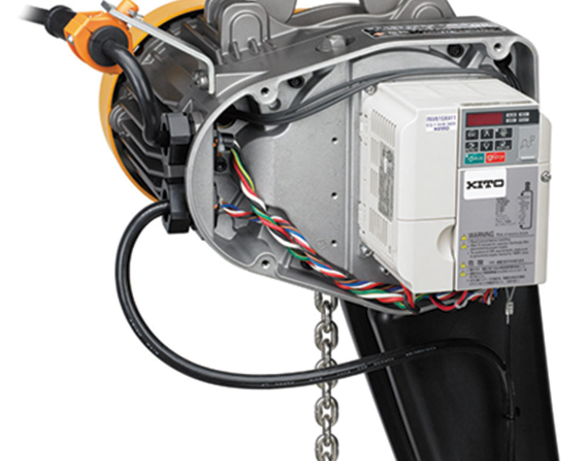

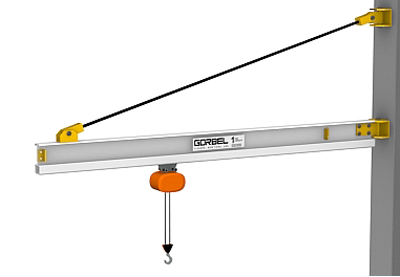

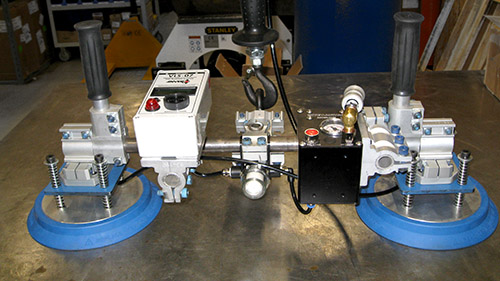

Acculift provides a solution from complete system design through to equipment installation. Often, our client’s needs go beyond that, and so do we: Acculift provides servicing, certified inspections, and training on all lifting equipment installs. Our S.I.T.E. program (Service, Inspection, Training, Equipment) covers you from floor to ceiling, from the beginning to the end, of your Acculift solution. We work together with you to develop solutions that will make your workplace safer and more productive.

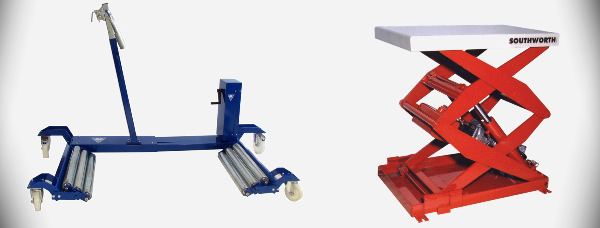

Our specialists assess facilities and ask questions that allow us to gain a better understanding of our client’s needs and goals. From that we can identify the best match between the need and our product offering. We can then formulate a unique solution, combining a mix of our equipment and services suited to the specific material handling needs of our clients. Acculift also provides after-installation support, servicing and inspections. Our solutions encompass overhead crane systems, workstation cranes, bridge cranes, jib cranes, fall safety equipment, and more.